Non-Ferrous Castings: Precision Rotomould, Blow Mould & Vac Form Castings [Complete Guide]

TP Castings offers expert non-ferrous castings with precision rotomould, blow mould, and vac form techniques for durable, high-quality components. Non-ferrous

TP Castings offers expert non-ferrous castings with precision rotomould, blow mould, and vac form techniques for durable, high-quality components. Non-ferrous

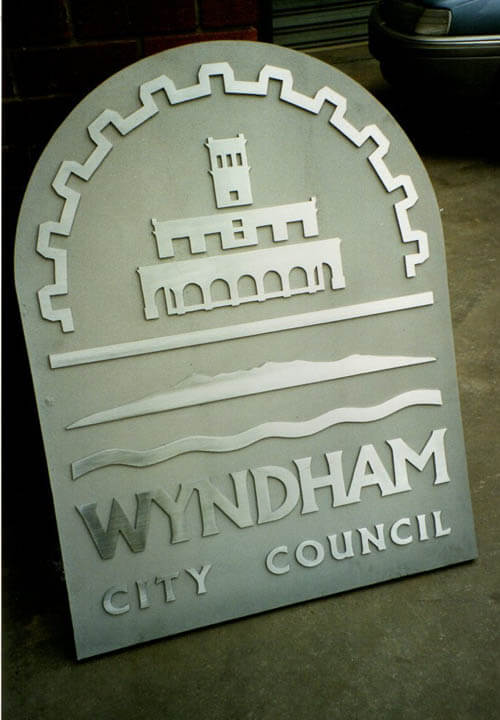

TP Castings offers high-quality non-ferrous metal casting services, delivering precision-engineered complex components with over 35 years of expertise. Non-ferrous metal

All the processes that define the metal-working industry are fascinating, but let’s pause in this diligent endeavour for a moment.

Instead of aimlessly pointing out the most common alloys used in die casting technology, why don’t we apply some intelligence

Two dominant forces in the castings industry shape and condition metal products. First, scorching temperatures liquefy rigid metals. The amorphous

The engineering labels employed here make these terms sound aggressive, explosively so, but the differences between shotblasting and sandblasting actually

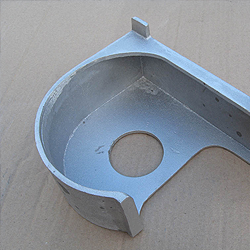

Simply put, non-ferrous castings don’t contain iron, so aluminium is part of this iron-free family tree, as is magnesium, copper,

Special finishes are often applied to non-ferrous parts at the post-processing stage. There are extra polishing and machining stages here,

Unique among high-end metal casting techniques, the rotational moulding process uses radial momentum to direct liquid metal flow. The equipment

The goal of this clash of the furnaces is to create a differential review, a critique that looks closely at

Negative impressions form the backbone of the metal casting industry. We’ll hold off on listing the various mould materials for

Non-ferrous metal castings are equipped with unique properties, material characteristics that find their way into important engineering applications. But these