Enhance tool life with expert insights on TIR, hardness, and surface prep in blow-mould die castings. Trust TP Castings for precision and durability.

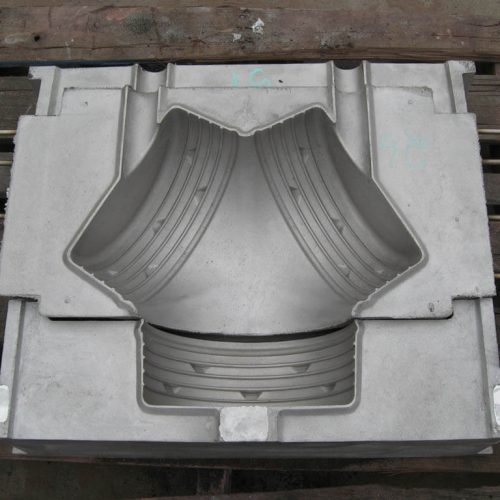

Tooling efficiency and longevity directly determine manufacturing quality and cost. Blow-mould die castings rely on precision, surface finish, and material hardness to perform consistently. Maintaining proper TIR, hardness balance, and surface preparation is essential to extending mould life and ensuring dimensional accuracy.

At TP Castings, we combine engineering precision with advanced metallurgical expertise to deliver die-cast components that meet and exceed performance expectations.

Achieving Optimal TIR for Consistent Performance

TIR (Total Indicator Runout) measures the total deviation of a tool or mould surface during movement or rotation. In blow-mould die castings, controlling TIR within tight tolerances keeps cavities dimensionally accurate and ensures precise part quality. Properly set and maintained TIR targets minimise uneven thickness, misalignment, and premature wear, enhancing overall tool reliability.

We recognise that every die has distinct tolerance requirements influenced by its material composition, production cycle, and the plastic being processed. Using advanced coordinate measuring machines (CMM) and CNC-controlled alignment systems, our technicians ensure each die meets precise TIR specifications—delivering longer tool life and consistent production quality.

Hardness: The Foundation of Durability

Tool hardness dictates wear resistance, impact strength, and stability under extreme heat and pressure, making it crucial for blow-mould die castings to perform reliably. Since steel grades react differently to heat treatment, each project requires a tailored balance to prevent brittleness or premature wear.

To achieve long-lasting durability, TP Castings uses advanced, controlled heat-treatment processes designed to deliver the perfect balance of surface and core hardness:

• Vacuum hardening – ensures consistent hardness and minimises distortion.

• Tempering – relieves internal stresses while maintaining toughness.

• Nitriding – adds a hard, wear-resistant surface layer for superior longevity.

Additionally, our engineers recommend specialised surface coatings to further boost performance. These coatings:

• Reduce friction during moulding operations.

• Protect against corrosion and oxidation.

• Extend overall tool life when matched with precise hardness profiles.

Through this meticulous approach, we ensure every die performs at its peak—offering exceptional strength, endurance, and reliability over time.

Surface Preparation: The Unsung Hero of Tool Longevity

Surface preparation is often underestimated, yet it’s one of the most critical stages in extending die life. A meticulously finished surface reduces friction, prevents material adhesion, and facilitates smoother ejection during moulding cycles.

Here are a few best practices we follow for surface optimisation in blow-mould die castings:

• Precision Polishing: Achieves uniform surface smoothness, reducing microscopic irregularities that cause wear.

• Grit Blasting or Lapping: Removes oxide layers and prepares the surface for coatings or treatments.

• Chemical Cleaning: Ensures all residues, oils, and contaminants are eliminated before final assembly.

• Protective Coatings: Adds an extra barrier against oxidation, abrasion, and high-temperature degradation.

These processes work in synergy to reduce thermal fatigue and mechanical stress, ensuring tools retain their structural integrity even under demanding production cycles.

Reliable Results Start with Precision-Engineered Blow-Mould Die Castings

TP Castings is a trusted Australian partner in precision engineering, material science, and tooling excellence. With proven expertise in high-performance die castings and a strong focus on innovation, we deliver unmatched durability, accuracy, and value. Our team works closely with every client to provide tailored solutions that inspire confidence and meet specific manufacturing goals.

Contact us to learn how we can help and why TP Castings is the preferred partner for all your casting needs.

Related Blog Articles:

Expert Blow Moulding Die Specialists: Precision Engineering for Perfect Production

Non-Ferrous Castings: The Ideal Choice for Vacuum Moulding Dies