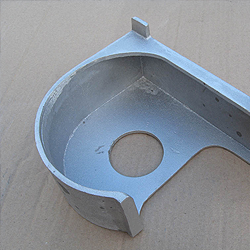

Non-Ferrous Castings: Precision Rotomould, Blow Mould & Vac Form Castings [Complete Guide]

TP Castings offers expert non-ferrous castings with precision rotomould, blow mould, and vac form techniques for durable, high-quality components. Non-ferrous castings, including materials like aluminium, copper, brass, and zinc, are